HTCI, Co. specializes in high quality complex castings, using three types of molding processes in the production of our castings. We serve a wide variety of casting markets, including those with the most demanding requirements and specifications, such as aerospace and OEM and automotive.

HTCI, Co. Mold Processes:

Plaster Mold Process

HTCI's ability to use the plaster mold process is unique in the industry. We have perfected this process to provide precision castings for aerospace, automotive, and other commercial needs and it consists of the following steps:

Plaster Mold Tooling Plaster Mold With Core Installed

Tooling:

Patterns are built out of water resistant materials, such as urethane, and mounted on cope and drag plates. Core boxes are developed when required from the same materials.

Plaster Mold:

Once the patterns are created, they are set-up as needed and a specially formulated plaster slurry is poured over them to form the upper and lower mold portions.

Cores:

If the part requires cores (to create passageways, etc.), a special plaster slurry is poured into a core box. When the plaster hardens, the core is removed from the box.

Mold Assembly:

Mold sections and cores are assembled to create the complete mold. This mold is then baked in ovens to remove any moisture from the mold.

Pouring Metal:

After bake-out, molten metal is poured into the molds.

Plaster Removal:

After the metal has solidified and cooled, the molds are broken away by vibration or high pressure water blasts. The castings are then cut from the gate and deburred.

Solid Mold Investment Process

The Solid Mold Investment casting process (aka Lost Wax process) is an economical way to produce high quality castings using a wax pattern.

Tooling:

Metal dies, usually aluminum, are produced from the customer's specifications.

Wax Injection:

High pressure injection systems fill the cavity in the dies with wax, producing a pattern.

Assembly:

Wax patterns are attached to gating (flow channels) and mounted to an aluminum plate.

Plaster Slurry:

Plaster slurry is poured over the wax pattern in a vacuum chamber to form a mold.

Burn-Out:

After the molds are created, the wax is melted out using a gas-fired dewax furnace.

Pouring Metal:

The "void" left by the wax will be filled by molten metal.

Plaster Removal:

After the metal has solidified and cooled, the molds are broken away by vibration or high pressure water blasts. The castings are then cut from the gate and deburred.

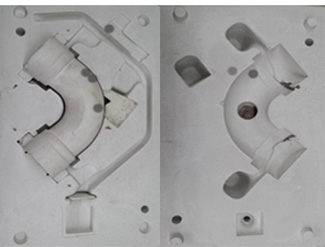

Precision Sand Process

Precision sand is an effective way to produce high quality castings using a no-bake sand mold.

Tooling:

Patterns are built using urethane tooling. Core boxes are developed when required.

Sand Mold:

Once the patterns are created, sand is mixed via an automatic mixing system using a specific percentage of airset binder. They are set-up as needed and the sand mixture is poured in them to form the upper and lower mold portions.

Cores:

If the part requires cores (to create passageways, etc.), core blowing machines blow sand into core boxes. The machine has a mixture of sand and chemical hardener that allows the sand to harden quickly.

Mold Assembly:

Mold sections and cores are assembled to create the complete mold.

Pouring Metal:

The molten metal is poured into the molds.

Sand Removal:

After the metal has solidified and cooled, the molds are broken away by vibration. The castings are then cut from the gate and deburred.

Technical Design Data

Cast Alloys

HTCI, Co. can meet the requirements of the majority of material specifications available, including MIL-A-21180.

Aluminum Alloys

319, 356, 357, 380, 535 (Almag 35)

C355, 203 (RR-350)

Tolerances

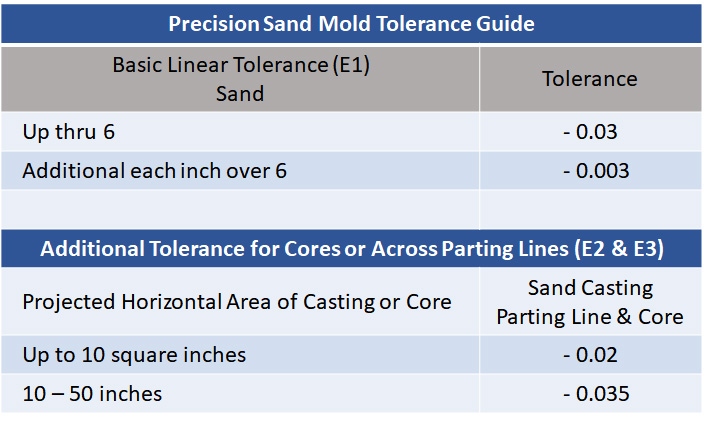

Normal cast tolerances are ± 0.01 for the first inch and then ± 0.005 inch per inch thereafter. Closer tolerances are available on selected dimensions.

Because cost increases in proportion to dimensional requirements, it is important that tight tolerances be assigned to functional areas and other tolerances be generous to obtain the most economical design. The following table indicates what generally can be held. Tolerances for geometric tolerancing are in proportion to the linear tolerances above.

Basic linear tolerance E1 call outs represent tolerances on one side of the parting line only. For dimensions that cross the parting line add E2 to E1. For dimensions including features in both the mold itself and in core add E3 to E1 and/or E2. The amount of additional tolerance for E2 and E3 is determined by the projected area of either the casting at the parting line for E2 or the projected area of the core in contact with the casting for E3.

For dimensions which cross the parting line, defined in part by core or are in some other way additive, these tolerances may require some expansion. The foundry should be consulted and good judgment is recommended.