In-House Services Capabilities

HTCI Co. also provides a portfolio of in-house services and special processes to meet our customers' complete solution needs, including:

Casting Consultation

HTCI has the "in-house" capabilities to make castings based on customers' specifications and expectations. As a result, customers can be assured of cost reductions to help all but eliminate timely delays typical from working with outside pattern manufacturing facilities.

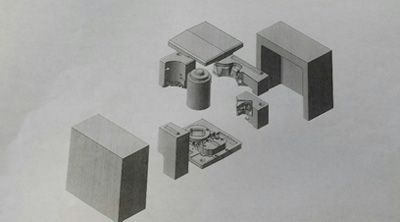

Tooling

In most instances HTCI Co. can address our customers' tooling and manufacturing requirements, in-house. As a result, customers can expect shorter lead times on projects, as well as, improved revision implementation lead times.

Rapid Prototyping

Rapid Prototyping (RP) is an innovative service that accelerates product development through the use of a 3D CAD file and advanced laser and machining technology such as 3-D printing and stereolithography. It is used to fabricate physical objects (prototypes) using CAD data and allows us to quickly test a design before moving forward with expense and time required for the investment or ceramic mold casting process. At times, it is also used to create single replacement parts for machinery that is out of production.

Rapid Prototyping (RP) is an innovative service that accelerates product development through the use of a 3D CAD file and advanced laser and machining technology such as 3-D printing and stereolithography. It is used to fabricate physical objects (prototypes) using CAD data and allows us to quickly test a design before moving forward with expense and time required for the investment or ceramic mold casting process. At times, it is also used to create single replacement parts for machinery that is out of production.

Our rapid prototyping services include:

- Rapid Prototype Castings - The hollow QuickCastTM style produces a clean burn-out when using the investment casting process.

- Rapid Prototype Machining - Prototypes from bar or plate stock can be machined in our CNC machine shop.

- Stereolithography (SLA) - The most popular RP method that uses a laser to solidify a liquid resin, one cross sectional layer at a time. Both solid (ACES) or quasi-hollow (QuickCastTM) models can be built and result in excellent model accuracy, a large build evelope, and smooth surface finishes.

Bridge Tooling

Bridge tooling is used for short production castings. RP models are duplicated into epoxy tooling.

Machining

To assist its clients with quick turn-around time, HTCI has a complete in-house machining facility. We have a vast array of equipment, including both 3-axis and 4-axis vertical machining centers (CNC). Castings can be purchased machined and ready for plating, assembly or anything else clients may require. In addition, we can supply prototypes machined from stock material such as 7075, 6061, etc.

Heat Treating Services

HTCI provides “In House” Heat Treatment services for our customers' casting needs, including full Heat Treatment hardening or simply Stress Relief, using AMS-2770 certified equipment.

Weld Repair

Repair welding is a necessary operation to correct defects in castings such as cracks and/or other problems in order to safeguard against product failures. HTCI has extensive experience providing qualified welding repair procedures and personnel in accordance with specified codes, specifications and standards.

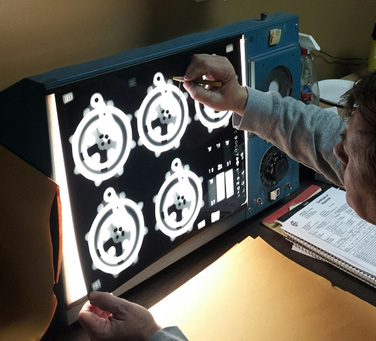

Non-Destructive Testing

According to the American Foundry Society, Non-destructive testing (NDT) involves a variety of methods or tests that can assure the quality of a casting without destroying it. Because a single test to measure mechanical properties, chemical composition, casting soundness or maximum service loads of a casting does not exist, a combination of nondestructive methods is typically used to document the soundness and quality of a casting.

HTCI provides the following "in-house" testing services:

- Radiographic Testing (X-Ray) - "In House" radiographic inspection services for a sample lot, or 100% lot inspection, results shorter lead times and less expense than outsourcing for testing.

- Flourescent Penetrant Testing - "In House“ Penetrant Inspection (Zyglo® Method), helps locate and identify surface defects

in order to screen out potential failure-producing defects, correct production problems and increase product uniformity. which reduces expense and lead time for your projects.

- Leak (Pressure) Testing - For castings specified as pressure tight or leak-proof, testing is typically done by sealing openings in the casting and pressurizing it with air, inert gas or water.

Mechanical Properties Testing

HTCI provides “In House” Aerospace Industry Standards Metallurgical certification for Elemental Content as well as Physical Strength Properties, saving our clients time and expense.

- Integrally Cast Test Bar - Test bars are in the same mold.

- Excised Test Bar - Test bars can be cut from designated areas of castings.